The pandemic revealed weak links in retail supply chains, but also drove levels of innovation and agility previously deemed impossible.

Now new threats have emerged – from inflationary pressures to staff shortages – placing global supply chains firmly under the spotlight once again. With logistics competitiveness playing a fundamental role in both margins and adaptability, global retailers must ensure their supply chains – from source to consumer – are fit for purpose.

These tough trading conditions have also placed strains on the individuals at the helm of retail operations; those tasked with implementing new solutions and technologies, and engaging talent to overcome such challenges.

So, against this backdrop, what must supply chain strategies look like in the year ahead? What level of logistics innovation can continue in an environment where margins are so stretched? And what are the areas retailers should postpone or even cease investment in?

Retail Week’s latest annual Supply Chain 2024 report, produced in partnership with GreyOrange, provides a blueprint for businesses to sustain growth even when the odds aren’t in their favour.

We’ve interviewed 50 UK supply chain and tech leaders to give you the opportunity to hear first-hand from those at the centre of the industry, and ultimately learn from them.

Methodology

Retail Week surveyed 50 retail leaders working in senior supply chain and IT positions in January 2023, who remain anonymous, to understand how they feel about their role, their leadership team and their investment priorities, challenges they and their retailers are facing, and what these leaders believe is required for the successful retail supply chains of the future. Retail Week has also compared the results with the same survey conducted in February 2022.

Asos says supply chain issues in 2021 have had the lingering effect of overstock

Asos says supply chain issues in 2021 have had the lingering effect of overstock

“The world needs to be prepared for more volatile and expensive global supply chains”

Currys said in December 2022 that stiff competition had damaged its margins

Currys said in December 2022 that stiff competition had damaged its margins

It has been a turbulent few years for retail supply chains, and many challenges remain – but there are signs of positivity emerging across the industry.

Starting with the challenges

In the months ahead, supply chains should expect new scrutiny and greater legislation as global efforts to reduce carbon emissions and tackle poor working practices rightfully continue.

These impending difficulties follow the significant impact on supply chains of the lockdowns throughout the pandemic in China – felt throughout 2022 – the Suez Canal blockage of 2021, intermittent industrial action at ports and in the delivery network, eight years of Brexit-related uncertainty and red tape, and general pandemic-induced confusion and delay.

Disruption to trade volumes due to the ongoing conflict in Ukraine, as well as rising inflationary pressures and expected policy tightening in advanced economies, are expected to continue too, according to the World Trade Organization forecasts published last October.

Some 74% of those questioned feel very or somewhat positive about the state of their business’s supply chain, compared with 62% last year.

Many retailers – including Asos in October 2022 – have noted heavy inventory loads that are reducing their margins as a result of much of the above.

In difficult times comes huge opportunity

However, our survey of 50 retail supply chain and technology leaders suggests hope springs eternal in 2023. Some 74% of those questioned feel very or somewhat positive about the state of their business’s supply chain, compared with 62% last year.

That represents progress, especially with some respondents telling us that “things are improving” with regards to supply chain management.

The criticality of supply chains across retail has been highlighted since the coronavirus crisis, with the disruption it caused contributing to stock shortages, manufacturing holdups and much more.

Now, then, is the time to double down on supply chain strategy. Developing differentiated and localised supply chains might be the answer, particularly when considering how delays and strike action will likely have a detrimental impact to goods importers.

Heath Zarin, founder of EV Cargo, a company that carries goods for companies including supermarket chains Sainsbury’s and Asda, told Bloomberg in July the world “needs to be prepared for more volatile and expensive global supply chains”. That should be a warning sign for retailers to keep evolving.

From Currys and DFS to Boohoo and Asos – not to mention the collapsed Made.com (see more on this in Chapter 1) – retailers of all shapes and sizes have reported that supply chain problems had negative impacts on their businesses.

Boohoo said in January that extended international delivery times were a contributing factor to a slump in sales in the four months to the end of 2022, and Asos noted last October that it was still feeling the impact of 2021’s supply chain delays in the form of holding too much stock. DFS cited Covid-related supply chain issues and double-digit cost inflation on raw materials, among other matters, as reasons for a 44.8% drop in profit for 2021-22.

Meanwhile, Currys said in December it encountered “gross margin erosion as some smaller domestic competitors are following aggressive growth strategies to gain share in a market that is structurally bigger following the pandemic”. This, and dwindling demand, led to competitors with overstock and heavy discounting eroding Currys’ margins.

All of this leads to the notion that agility, diversity of options, and an ability to continually evolve are prerequisites of a modern retail supply chain.

Over the following chapters, we’ll lift the lid to find out exactly what is going on in the inner workings of retailers’ supply chains and how to use this information to inform your strategy…

Despite the uncertainty in retail, the mood among the industry’s supply chain and IT leaders is becoming increasingly positive.

Only 36% of the supply chain leaders we interviewed have considered leaving their job in the last year. This is a dramatic fall compared with the 56% that felt the same way in our February 2022 study, when sentiment was low in the immediate aftermath of the Covid-19 crisis.

A significant 96% of those working in retail supply chain and IT said they are very or somewhat supported by leadership – with 35% saying they feel more supported than they did in 2022. Some 75% of retail’s supply chain and tech leaders believe their CEOs and executive board members understand the current pressures upon them, while 74% are generally positive about their business’s supply chain.

There are still a quarter of supply chain and IT leaders who do not feel their senior team understand the difficulties they face

This raft of confidence from the profession suggests the radical structural overhaul undertaken by so many retailers in 2020-21 has resulted in greater supply chain resilience and readiness.

However, there is always room for improvement because – as outlined in our opening – there are always going to be new supply chain challenges to meet.

Indeed, there are still a quarter of supply chain and IT leaders who do not feel their senior team understand the difficulties they face. And, among the 35% that have considered quitting their jobs in the last 12 months, they cite ‘lack of support’, ‘underappreciation’, ‘delays in promotions’ and the fact that ‘stress has gone up’.

The polarisation in IT and supply chain leadership is evident throughout our interviews, with half of respondents saying that tech leaders are becoming more involved in their supply chain activity and there are fewer silos. But this of course indicates that 50% of people are not seeing this, meaning there is still more work to be done to connect these areas.

Positively, the survey shows investment in retail supply chains is growing; 52% cited an increase in their investment and budget over the past 12 months. This is compared with 36% who said the amount of supply chain investment hadn’t changed in the last year.

Fortnum & Mason withheld sending goods to most European Union countries throughout 2022 as a result of post-Brexit red tape

Gymshark's Laurent Madelaine's "expertise within both retail and fashion will bring an invaluable new layer to our supply chain" says CEO Ben Francis

Gymshark's Laurent Madelaine's "expertise within both retail and fashion will bring an invaluable new layer to our supply chain" says CEO Ben Francis

“Many businesses seem to have gone into a holding pattern — uncertainty rules and the best plan is deemed to be do nothing... but making bold moves in difficult times can and does yield benefits”

Jo Graham is now haircare brand ghd's first-ever chief information officer

Jo Graham is now haircare brand ghd's first-ever chief information officer

Investment in retail supply chains is growing; 52% cited an increase in their investment and budget over the past 12 month

Challenges and how to deal with them

According to our research, the top three pain points for the 50 people leading retail’s IT and supply chain functions are:

- Hiring supply chain staff and managing employee turnover

- Navigating price increases due to inflationary pressures

- Brexit complications

There are retailers exemplifying these two pain points regarding inflation and Brexit. Made.com, for instance, cited sharp increases in supply chain costs in the preamble to its collapse in October 2022.

Fortnum & Mason, meanwhile, withheld sending goods to most European Union countries throughout 2022 as a result of post-Brexit red tape. The luxury department store’s sales continue to rise, but it is missing out on part of its business that was generating between 5-10% of its sales previously. Not far behind in the list of pain points cited by supply chain leaders were staff working conditions, sourcing stock and managing overstock.

Asos’s decision to set up a strategic partnership with discount marketplace Secret Sales in January 2023 highlights the inventory overstock issue. Launching initially in the UK, the Asos-Secret Sales tie-up will involve selected discounted items shifting from Asos’s website to that of Secret Sales. The plan is to continue to update this stock over time, as part of a dedicated strategy by Asos to address its high inventory levels following the pandemic.

Hiring is more important than ever

With so much at stake and a list of priorities requiring significant direction, UK retailers are refreshing their supply chain and IT leadership. Supply chain staff are moving from the backroom to the boardrooms.

Gymshark, for example, has reached the stage of maturity where a supply chain boss has become vital. With operations ongoing in multiple territories, growing revenue (up by 54% year on year to £401.9m in 2020-2021), its October 2022 store/events hub opening in the heart of London’s West End, and founder Ben Francis now taking full responsibility for the business as CEO, Gymshark appointed Laurent Madelaine as its first chief supply chain officer in January 2023.

Madelaine arrived from fashion brand Lacoste and previously worked for Sears, Tesco and Carrefour, and thus brings huge traditional retail expertise to a digital-born, scale-up brand.

Showing foresight in terms of what the brand needs as it grows, and explaining Madelaine’s multi-faceted role, Francis said: “We’re committed to creating the best possible product, but it absolutely has to be sourced from the right place.

“Laurent’s sourcing experience, which has taken him all over the world, combined with the importance he places on community, makes him an incredible addition to the team. His expertise within both retail and fashion will bring an invaluable new layer to our supply chain.”

Highlighting the need for retail reinforcements and an expertise within both retail and fashion will bring an invaluable new layer to our supply chain ability to think differently to navigate the specific challenges the industry faces in the current climate, John Lewis Partnership (JLP) recruited an executive-level chief transformation & technology officer in November 2022.

Zak Mian joined the John Lewis Partnership with more than 30 years' experience

Zak Mian joined the John Lewis Partnership with more than 30 years' experience

Zak Mian, most recently group transformation director at Lloyds Banking Group, is now leading JLP’s transformation, technology and change teams, and brings more than 30 years of experience in such fields.

Indeed, relevant tech and transformation hires are more important than ever. Asos promoted commercial boss Jag Weatherley to corporate transformation director last November, while Jo Graham left her CIO role at Boohoo Group in December 2022 to assume the same position at hair products brand ghd, which had never previously employed a permanent CIO.

Jag Weatherley was promoted to corporate transformation director at Asos, reflecting the importance of these new roles

Jag Weatherley was promoted to corporate transformation director at Asos, reflecting the importance of these new roles

These companies are looking at the challenging landscape and tackling it head on. That is the correct way to approach hiring in a volatile environment, says the boss of executive search firm Clarity, Fran Minogue.

“Many businesses seem to have gone into a holding pattern — uncertainty rules and the best plan is deemed to be do nothing,” she explains. “But history shows that making bold moves in difficult times can and does yield benefits. During the pandemic, those that acted decisively and grasped the opportunities born out of adversity emerged fitter and stronger. That can be the case again.”

She adds: “The first thing announced in a recession is often a hiring freeze and/or headcount reduction. But those that make ambitious, growth-oriented appointments will be rewarded with a broader and richer dialogue when it comes to scenario planning and strategic debate, and will be faster out of the blocks when markets turn upwards again.”

Unlike in Chapter 1, where attitudes and supply chain leadership have evolved markedly on 2022, in the first mile it is clear from our interviews that there is more continuity over the past 12 months. Our interviews show retailers’ utmost supply chain and IT priorities for 2023 are the same as in our survey for 2022: data analytics and real-time visibility, and achieving more accurate stock levels.

As with last year, too, bringing sourcing closer to the UK is the fifth-highest priority for retail supply chains. A quarter of respondents said this, suggesting Brexit continues to change the shape of globalisation from a UK retail perspective.

However, it is the secondary priorities for 2023 that underline a fascinating shift from last year.

While improving warehouse and factory working conditions, upskilling and reskilling existing staff, and hiring more logistics staff completed the top five priorities in 2022, these have been replaced in 2023 with general warehouse automation, and implementing artificial intelligence (AI) in the warehouse.

Look Fantastic and Cult Beauty parent company The Hut Group (THG) is a good example of a retailer investing in more automation, with its Manchester warehouse now able to process up to 500,000 items a day thanks in part to 250-plus picking and packing robots supporting staff at the site. There are plans to replicate this site in other countries in which the company operates, as THG sees the value in this type of facility.

The most popular solutions for dealing with supply chain transformation in 2023 highlight a growing shift towards technology reliance, too. While upskilling and reskilling frontline store staff to support on fulfilment, and diversifying supplier bases were key focuses one year ago, there is now more demand for investing in tech.

Some 16% said investing in other technology and tech innovations was the main way they were looking to bring about supply chain transformation, while 12% said they would be investing in warehouse robotics automation.

Like last year, collaborating with more third parties, including tech platforms, retailers and industry experts, remains popular in terms of the methods supply chain and IT leaders wish to use to navigate the challenges of first mile.

AI, warehousing and transformative tech

One topic to arise at the Confederation of British Industry Annual Conference in Birmingham last November, at which prime minister Rishi Sunak addressed delegates, was the lack of automation partners present in the UK.

The supply chain industry in the UK is keen to work with the government to develop the sector onshore. This could be an area of development, especially if chancellor Jeremy Hunt’s vision of creating a Silicon Valley equivalent in Britain is realised.

Supply chain solutions provider GreyOrange is one of the companies filling the gap for retailers, working with H&M in the UK and other brands to help automate warehouses and drive efficiencies. The business is also working to demystify AI in the supply chain and make it easier for retailers to understand.

“Piloting AI and robotics won’t help – retailers have to invest and embrace it fully to really make it work”

For instance, Akash Gupta, GreyOrange chief executive and co-founder, says AI at the simplest level is machine learning that is helping retailers make more informed decisions with their inventory and avoid grappling with data.

“While it’s mainly the social media giants that we see in the news maximising on AI and robotics, there are many retailers also making the opportunity real,” he explains. “It’s not an if, it’s a when. Retailers need to invest in this area or they will get left behind. Walmart, for instance, is using AI to make ecommerce more affordable. As a retail giant, it relies on optimising large warehouse facilities to meet consumer demand and so it is using GreyOrange’s AI Greymatter as its operating software to support fulfilment.”

Meal kit service Gousto has “double-digit lower” costs at its new automated production centre

Meal kit service Gousto has “double-digit lower” costs at its new automated production centre

Gupta argues that AI investment can enable retailers to manage their inventory and understand what items sell well with others and where those items should be placed. But retailers need to think beyond efficiencies and consider the transformative potential of the technology.

“AI and robotics are well-established technologies, well-established in multiple use cases from manufacturing to accounting. AI is here to stay so the emphasis for retailers is not on deciding if you need it, but on exploring how best to leverage it.”

With inflation at its highest levels in the UK since 1981, the cost of doing business is growing for retailers. Timo Boldt, CEO and founder of meal kit subscription provider Gousto, acknowledges this. He says investments the company has made and will make in supply chain tech are helping to keep prices low for its customers – this will be particularly key given the business announced it had to raise millions in additional funding in January 2023 to navigate the volatile trading period.

The most forward-thinking retailers are investing more in their warehouse staff

“It’s no secret that Covid caused a lot of supply chain dysfunction, and Putin’s war is only exacerbating the issue,” Boldt said, talking in April last year. “We’re seeing huge spikes in wheat and beef prices in the UK and across the world. But we have the best people you can have [in our logistics team] and I’m hugely proud of what they’re achieving. And then the ability to trade the menu from a technology perspective allows you to be 50% more agile than any supermarket could ever be.”

Explaining further, he said the tech Gousto has in place enables menus to dynamically change to fill gaps in product availability without affecting the service for customers. There is also a fully automated production facility in Warrington, which opened in the summer of 2022, that the CEO said can be run at a “double-digit lower” cost than earlier production plants, which helps “soften the blows and protect the price point”.

Merging tech and talent in first mile

Despite automation and tech trumping people-specific investment in this year’s survey, it should not be a case of either or in the first mile of the supply chain. Increasingly, retailers are automating certain functions while also finding neat ways to combine tech with manpower.

The most forward-thinking retailers are investing more in their warehouse staff, both to retain and attract sought-after talent but also to make their warehouse environments more appealing to work in.

Aldi UK increased pay rates for more than 7,000 warehouse workers from February 2023, with CEO Giles Hurley saying it recognised “the hard work and contribution our colleagues make in serving communities across the country”.

Meanwhile, Currys invested more than £250,000 in a fleet of robotic exoskeleton suits ahead of peak period in October 2022 to help colleagues from logistics partner, GXO, work safely and efficiently through the busy festive period.

Currys' robotic suits help with posture and lifting practice

Currys' robotic suits help with posture and lifting practice

Used at Currys’ tech-enabled Newark site, the suits help staff to carry out their physical day-to-day tasks, putting less pressure on their joints and muscles when lifting heavy loads. The move was to prevent injuries in the manual handling environment, with the suits worn like a backpack to give workers assistance to the lower back with each lift.

The equipment has an AI-based ‘Smart Safety Companion’ ergonomics early warning system to alert of signs of poor posture and incorrect lifting practices. Lindsay Haselhurst, Currys chief operating officer, said: “As the number one technology retailer in the UK, we aim to have state-of-the-art tech throughout our supply chain.”

Fashion retailer New Look is another company investing in first-mile supply chain technology, putting order and warehouse management high up its list of major work in the coming years. The business views this as a key way to build the infrastructure required to serve consumers in new ways. Back-end transformation will enable customer-facing improvements, is the theory.

In a press release issued in March 2022, Tristan Holiday, logistics director at New Look, said he wants to “constantly review our fulfilment network and realign it accordingly, matching the ever-changing needs of our customers”. Investment behind the scenes is expected to be a catalyst for such a model.

However, some retailers are favouring automation in place of headcount. In February 2023, Sainsbury’s announced it was cutting 1,400 warehouse jobs as it rolls out a £90m investment in automation to modernise its general merchandise logistics network. The retailer said it would be offering the “opportunity [for staff] to explore alternative roles within Sainsbury’s and Argos”, with the shift intended to “reduce costs, so we can invest where it will make the most impact for our customers”.

Partnerships or part of the team?

All of the aforementioned investment highlights the power of partnerships in the first mile of the supply chain. In such a technologically transformational time, most retailers are inevitably going to look to experts in the space to support their goals, modernise their warehouses, and take them down an AI-enabled route.

At the start of 2023, Hotel Chocolat announced a joint venture (JV) with Tokyo-based Eat Creator Corporation, which would bring specific supply chain expertise in Japan to the retailer as well as investment in the company. The move came after Hotel Chocolat was forced to write off nearly £30m following the collapse into administration of its Japanese arm. Eat Creator will manage localised chocolate-making making facilities and operate 21 stores in Japan, with Hotel Chocolat holding a 20% stake in the JV and collecting brand royalty revenues.

Hotel Chocolat founder and CEO Angus Thirlwell said: “Retailing internationally is really hard and very few people get it right the first time. So we decided to do a big change there and look for a new partner that had expertise in local supply chains and would also put the capital in themselves rather than us.”

Interestingly, Hotel Chocolat is not the only UK retailer to forge such a strategic partnership with a supply chain business in the last year. Marks & Spencer purchased its logistics provider Gist in July 2022 to take control of its end-to-end food supply chain.

Prior to the deal, Gist provided the majority of M&S Food logistics services. For an initial cash offer of £145m, with a further £110m plus interest to be payable on certain conditions, the retailer has taken control of its supply chain through this unusual acquisition.

M&S CEO Stuart Machin said: “M&S has been tied to a higher-cost legacy contract, limiting both our incentive to invest and our growth. The last two years have shown what can be achieved by working collaboratively. This has given me confidence that now is the time to take action and remove an impediment to our growth. We have therefore acted decisively to acquire Gist, taking control of our food supply chain for the first time in our history.”

The investment chimes with Retail Week analyst forecasts that, by 2026, M&S will overtake John Lewis as the seventh-largest UK retailer. Our analysts predict that by 2026/2027 financial year, M&S will generate £12.45bn in UK sales, compared with John Lewis’ forecast £11.70bn.

Hotel Chocolat is turning to local expertise to reinvigorate its business in Japan

Hotel Chocolat is turning to local expertise to reinvigorate its business in Japan

Marks & Spencer brought its logistics in house with the purchase of provider Gist in 2022

Marks & Spencer brought its logistics in house with the purchase of provider Gist in 2022

The last mile of supply chain is more complex than ever; retailers are having to battle against consumer demands for the often contradictory fast, convenient – and sustainable – delivery, all while navigating rising return rates. Indeed, the last mile is often reverse logistics carrying an unwanted item back into the business.

So what are retailers doing about making it all operationally sound, and where does the focus lie?

The list of priorities from IT and supply chain leaders suggests first-mile investment comes first, but retailers know they can’t abandon the customer-facing elements of their proposition. The prioritisation could also be because final-mile transformation was high on the agenda during the pandemic so it’s less of a focus now.

Indeed, reducing the cost of returns is a priority for 22% in our interviews, which compares with 28% who said the same thing last year. The drop is probably because there is a movement already well under way in the industry to start charging for online returns.

Making returns pay

In the 12 months since our last report was published, Boohoo and Zara in the UK have started charging customers if they wish to return items via a courier. Boohoo now charges £1.99 per parcel while Zara now charges £1.95 – Zara will not charge if the item is dropped off in a store.

As of 2023, New Look is also trialling charges for online returns with a £1.99 fee to return items via post. As with Zara, customers can continue to return online orders to New Look stores for free.

“By charging for return(s), we can keep our sales price lower”

Rachel Troke, senior product manager for web and mobile at New Look, said at Metapack’s The Delivery Conference (TDC), held in London on 7 February, that the fashion retailer has started testing paid returns as a way of “recovering our costs” online rather than making money from the fees.

“People are returning [items] because they just don’t like the feel or look of it, so actually we’re never going to get that return rate down really low,” she explained.

“Therefore the offset is, by charging for return(s), we can keep our sales price lower, and that is why we’ve introduced it.”

However, charging for returns is not for every retailer. Also talking at TDC was JLP general manager for customer delivery and collection operations Gary Page, and The Very Group’s head of logistics Chris Haighton. Both said they did not want to add such friction to the customer experience and therefore affect purchasing decisions.

“We want to keep returns free as long as possible”

Page commented: “I think free returns is a really important part of the proposition, and customers have enjoyed that for several years. If you want to continue providing something that customers value, then free returns are part of that.”

Haighton added: “We want to keep returns free as long as possible. Giving [customers] the confidence they can return quickly, easily and without hassle is a major part of the buying decision.”

Haighton also said that The Very Group trialled paperless returns, meaning customers were directed to an online portal to process any unwanted purchases. However, he noted it wasn’t well received by shoppers, so paper has been reintroduced – albeit temporarily.

“Our ambition is to remove the paper completely because it is better for the environment, there is a cost saving associated, and we get much more control and visibility over the returns chain,” he noted.

“I think in order to implement it effectively, we’re going to have to offer some real value exchange for the slight additional friction we’re adding to the process. Possibly that might be credit for the customer at the point [at the] CollectPlus or Post Office counter rather than waiting for the item to come back before it is credited.”

Next and Uniqlo have charged for online returns for some time now, last year The Hut Group and Mountain Warehouse joined ship, and H&M is considering it in some markets – though hasn’t implemented charges yet – highlighting an industry divide on this subject. Some see it as a necessity to cover operational costs and the rising fees involved with shipping goods, but others view it as something that would be too much of a customer turn-off.

As Jim Rudall, head of revenue at Shopify, said at TDC, there is another way of approaching the returns dilemma.

“Get to the root cause of returns,” he advises. “Do you really understand why your customers are returning? [Consider] how you build an experience which reduces their propensity to return in the first place.”

On-demand delivery and other fulfilment methods

Only 20% of the supply chain and tech leaders we surveyed believe on-demand delivery services to be transformative for the future of their business’ supply chains but for 18% it is currently their top supply chain and investment priority.

Last year this was a priority for 22% of respondents, so the slight dip in interest in this area perhaps tells a story that the industry is moving away from the ‘test and learn’ stage with this innovation.

Enabling click-and-collect from stores is the lowest priority for the supply chain and IT leaders

There has been some significant consolidation in the market, too. Following Getir’s acquisition of rival Weezy in the UK in 2021 for an undisclosed sum, the former also acquired Gorillas in a $1.2bn deal in December 2022. Jiffy – another player in the UK – halted its delivery operations last year, as companies in the space continue to make things stack up financially.

For Deliveroo and Just Eat, though, retail partnerships continue to grow. Asda teamed up with Deliveroo in August 2022, and in January this year Sainsbury’s signed a deal with Just Eat to support quick food delivery from 175 of its stores. Meanwhile Boots expanded its Deliveroo partnership to 750 products and 125 UK stores last August, after what was clearly a successful initial trial period.

Interestingly, enabling click-and-collect from stores is the lowest priority for the supply chain and IT leaders in our survey. There are lots of factors at play here, but many retailers invested in this during the pandemic, so it is likely to be a sign of market maturity.

Moreover, with the continued emergence of companies providing out-of-home pick-up points, the demand for click-and-collect could be shifting into this area.

JLP’s Page said: “Customer behaviour has changed a lot since lockdown. Going into lockdown, about half of our customers used click-and-collect and half home delivery. During the height of lockdown that was down to 20% click-and-collect, and it is only recently that this has begun to rise again.

“Are we at the new norm, or will things continue to change and evolve?”

Teamwork makes the dream work

Some 54% of IT and supply chain leaders we interviewed believe they are working more closely with store staff on fulfilment and operations than they were two years ago, yet 64% believe there is greater staff training needed for fulfilment and supply chain support.

Compared with 12 months ago, not much has changed – although there is a slight move towards retailers saying they are collaborating less with store colleagues. Morrisons, for example, reduced the number of stores it uses for online picking by 50 in 2021 after demand subsided after the height of Covid-19 – which is an illustration of the slowdown in ecommerce since the height of the pandemic.

In another new method of fulfilment trialled earlier this year, Sainsbury’s introduced a drive-through concept.

The Flourish Fuelling Station opened on 25 January, running overnight between 5pm and 8am until Friday 27 January at the retailer’s petrol forecourt in London Colney, St Albans, to support night-shift workers with hot meals. Sainsbury’s is still mulling future iterations of this based on the results of the trial, but it could be a new fulfilment channel to watch out for in the future.

International inspiration: Drones take to the skies

Walmart announced figures in January 2023 showing its innovation in the last-mile delivery space, with 36 of its stores in the US reportedly now providing drone delivery hubs operated by DroneUp, Flytrex and Zipline. The first store offering this only started doing so in 2021, highlighting a rapid rise in Walmart’s capability.

The grocery giant claims to have completed more than 6,000 drone deliveries in 2022. With fulfilment within 30 minutes, drone delivery where it is feasible is an attractive – and, at present, novel – proposition. Walmart says the most popular items delivered by drone to date are: Great Value Cookies & Cream Ice Cream, 2lb bag of lemons, rotisserie chicken, Red Bull and Bounty paper towels.

Shoppers pay a $3.99 (£3.33) charge per delivery with a weight limit of 10lb under the guidance that “if it fits safely it flies”.

Meanwhile, in Australia, Coles has partnered with Wing to offer rapid delivery by drone to customers in Queensland. Customers can order from 500 essential items, which are picked by store staff and delivered using drones co-located in the grocer’s store car park.

Is this coming to the UK soon? Well, as we explain in the following chapter, Boots has trialled drone delivery of medicines in England and there is an expectation it will become a more prominent part of ecommerce fulfilment in the future.

Watch this (air)space.

Walmart's drone delivery partners include DroneUp

Walmart's drone delivery partners include DroneUp

Coles uses Wing drones from its store carparks

Coles uses Wing drones from its store carparks

How can global retailers future-proof their supply chains?

According to the supply chain and tech leaders interviewed, there is a disconnect between what is wanted from their retailer’s supply chain investment strategies and where the money is actually being directed. The same problem was found in our 2022 survey. Below, we outline the solutions our interviewees think retailers should be backing.

Solution 1: Warehouse automation

While warehouse automation is among their retailer's 2023 priorities, a significant 38% of the supply chain and IT executives surveyed said their retailers were not making the most of the solution in their supply chains. The reasoning for this was mostly due to a lack of budget.

Retailers risk falling behind, with those embarking on warehouse automation in recent years talking up its impact, including The Very Group.

The Very Group is investing in warehouse automation

The Very Group is investing in warehouse automation

In October, for example, the group said its highly automated East Midlands fulfilment centre, Skygate, processed 36.2m items in the financial year to July 2022. It also dispatched 14.8m customer orders, with the fastest order being dispatched in 16 minutes, as well as dispatching 102,000 orders on its busiest day alone. As part of the work at Skygate, Very acknowledged it has become more agile in its global sourcing operation by shipping to ports in the north of the UK, with containers heading directly by rail to the site.

Solution 2: Driverless delivery

Driverless delivery was cited as the second most transformative technology (50%), while video streaming and ordering services were the third most transformative tech for supply chains (48%). Co-op Food remains a UK industry outlier in its usage of driverless delivery, and the grocer continues to roll out the use of automated delivery robots to fulfil online customer orders in Milton Keynes, Northampton, Cambourne, Cambridge, and now Leeds.

The Co-op partnered with Starship Technologies and Leeds City Council to introduce the robots to the Yorkshire streets in November 2022. Consumers can make orders on the Starship app, schedule their delivery, then drop a pin where they want their delivery to be sent. They can watch the robot travel in real-time via an interactive map, too, and unlock their goods with the app.

Chris Conway, ecommerce director at The Co-op, said: “Co-op is committed to exploring new and innovative ways to increase access to its products and services. Our members and customers lead busy lives and so ease, speed and convenience is a cornerstone of our approach.”

Starship Technologies provides robot delivery, and recently partnered with the Co-Op

Starship Technologies provides robot delivery, and recently partnered with the Co-Op

Boots has taken a step forward in use of aerial drones, testing out medicine deliveries via this method on the English south coast in July 2022 – with goods flown across the Solent from Portsmouth to the Isle of Wight. It is all very much in test mode at the moment, but the retailer expects this type of delivery to arrive in the future.

Rich Corbridge, CIO of Boots, said: “We will be looking at how much time we can save, as well as how we can incorporate drones into our medicines supply chain to create economic efficiencies too. We want to prepare now for the wider use of this technology in the future.”

Solution 3: Scaling back on micro-fulfilment

In another sign of disconnect between what supply chain and tech leaders want and the approaches their retailers are actually taking, our survey found micro-fulfilment is what leaders believe to be the least transformative future supply chain innovation. However, Walmart in the US, and UK retailers Ocado and Tesco have adopted this format in the last few years.

Tesco opened its sixth smaller urban fulfilment centre (UFC), in its Bar Hill Extra store, in January 2023. Like others before it, it features a dedicated online picking hub for its delivery van fleet as well as click-and-collect. But it has said that it will not open as many as it had previously planned, so it seems there are fewer benefits to this model than first thought.

Forty percent of supply chain and tech leaders believe the government is not doing enough to alleviate the burden on retail supply chains

Our interviewees have told us what they want from their retailers, but what do they want to see outside of their businesses – particularly from government?

Gripes with government

Despite the pockets of positivity already referenced, several years of problems are starting to grate on retail’s supply chain leaders. Many want the government to step up.

Forty percent of supply chain and tech leaders told us they believe the government is not doing enough to alleviate the burden on retail supply chains. This is a marked increase on the 24% who felt policymakers weren’t doing enough in our 2022 survey.

In particular, as the industry looks to the future, leaders want the government to address the cost of overseas imports, remove red tape, invest in more technology, and crucially – according to one – “talk with the industry to support our needs”.

Another interviewee explained the situation: “Cost of product is at an all-time high for importing from overseas which needs addressing immediately as well as the rise in transport costs such as fuel and labour pay – these need addressing to help businesses thrive.”

To mitigate concerns, the government could introduce cost thresholds, improve import controls, and invest in new technologies to streamline future processes and reduce importing frictions. Positively, the government is currently looking at new models to address the latter and is set to bring in a new controls regime at the end of 2023. The new Target Operating Model will be based on a better assessment of risk and will harness the power of data and technology. It is also launching the UK Single Trade Window – a new digital gateway that will help traders to more easily move goods globally.

Sustainability matters

Each year, retailers are faced with more sustainability-related legislation in line with society’s drive to reach a position of net zero carbon emissions that scientists say is crucial for the future health of the planet.

In February 2022, the European Commission proposed what is effectively an EU supply chain law. Once brought into play, it will require certain companies to meet due diligence obligations with respect to human rights and environment across their supply chains. The directive will apply to both EU and non-EU companies that either have a significant number of staff in the territory or meet a certain turnover.

Tesco is planning a rollout of its electric delivery vans following launch in Scotland

Tesco is planning a rollout of its electric delivery vans following launch in Scotland

The finer details are still being mapped out, but it is a sign stricter rules – and punishments – based on how businesses run their supply chains are imminent.

Over the last 18 months, there have been a plethora of retailer announcements relating to sustainability. Amazon has removed plastic air pillows from its packaging, Tesco has rolled out electric-powered vans in Scotland ahead of what is expected to be a wider UK roll-out, while all major retailers are setting individual carbon reduction targets.

Many – including Burberry, Pentland Brands, and Richemont – have aligned with the Science Based Targets Initiative, which provides a framework to follow over several years to take carbon out of their respective supply chains.

Supply chain leaders' top picks

Amazon and Tesco were the two retailers and brands named in the survey as having the most successful supply chain and operations management, so what is it about them that stands out?

Amazon in focus

Amazon’s logistics and supply chain has been the foundation of its success in the UK in the last two decades, with traditional retailers looking to replicate the tech company’s model wherever possible. Amazon’s ability to provide rapid and consistent next-day delivery, pick-up lockers in third-party locations, and a Prime subscription service that engenders significant loyalty has transformed retail and influenced others.

The service, as of the end of 2022, is supported by 24 UK distribution centres. It is also continually investing in technology to automate and optimise its warehouses and logistics, most recently via the acquisition of Cloostermans, a Belgium-based mechatronics manufacturer that has tech that can stack heavy pallets and totes or package products together for customer delivery.

Robotic arms are being developed to handle packages in the Amazon warehouse network before they begin their delivery journey. The latest iteration, Sparrow, was introduced in November 2022. It can detect, select, and move individual products by leveraging computer vision and AI to handle items.

If the strength of a business’s supply chain is measured by others using it, then Amazon is number one. Around 50% of items sold on Amazon are from third-party sellers, via Fulfilled by Amazon (FBA), under which vendors pay Amazon to hand over picking, packing and fulfilment of items for delivery to Prime members.

But as has been reported in the early weeks of 2023, Amazon is not immune to market conditions, given its decision to close three warehouses in the UK at the potential cost of 1,200 jobs. Its retail sales in the UK actually slipped last year, when using its reporting currency of US dollars.

The drop from $31.9bn (£25.9bn) in sales in 2021 to $30.1bn(£24.9m) in 2022 is a significant landmark for what has been such a consistent growth company over the last two decades.

Amazon said its shipping container costs had more than doubled compared with pre-pandemic rates and that, together with wage inflation, had created $2bn (£1.66bn) in additional costs. Amazon plans to reduce its fixed-cost leverage by optimising its fulfilment network and taking up excess capacity through expansion of its FBA network.

It goes to show that even the best-regarded supply chains need continual adjustments in order to stay operationally efficient. Amazon’s closures highlight a change in strategy as it focuses on cost reduction and the optimisation of its network.

Sparrow is the latest iteration of Amazon's robotic picking system

Sparrow is the latest iteration of Amazon's robotic picking system

Amazon has 24 distribution centres in the UK

Amazon has 24 distribution centres in the UK

Amazon first introduced drone delivery in 2022

Amazon first introduced drone delivery in 2022

Tesco DCs benefit from automatically updated ordering

Tesco DCs benefit from automatically updated ordering

The retailer is aiming to constantly improve efficiency

The retailer is aiming to constantly improve efficiency

Tesco in focus

Innovation in the supply chain is a priority for Tesco, and it utilises technologies such as voice-picking and automation to help reduce lead times from when a grocery shopper orders their shopping to when it arrives.

Over the past five years, Tesco has been using analytics to predict demand and make its supply chain data more accurate. This has enabled it to reduce waste, make better use of promotions, and match stock to demand.

The supermarket chain uses modelling to improve its understanding of the correlation between weather data and sales patterns, as well as to predict levels of demand by region. The group’s ordering systems are automatically updated in real time based on what customers actually buy.

There is ongoing work at Tesco to reconfigure its supply chain to ensure it is fit for a multichannel environment. Its distribution strategy rests on two main pillars: achieving a greater understanding of which products are needed by the stores, and improving efficiency of distribution processes, systems, and network of distribution centres.

In recent years, that has involved the consolidation of DCs – closing smaller ones and running larger sites, as well as the aforementioned experimentation with UFCs.

On-demand delivery is another investment area for Tesco, despite our survey showing a decreased focus among retailers with it only a priority for 18%. In March, Tesco announced it had expanded its Whoosh rapid delivery service to 1,000 UK stores – 25% ahead of its target – with customers now able to now order 2,500 to 4,500 essential products in as little as 30 minutes, with delivery set at £2.99 on orders of £15 or more

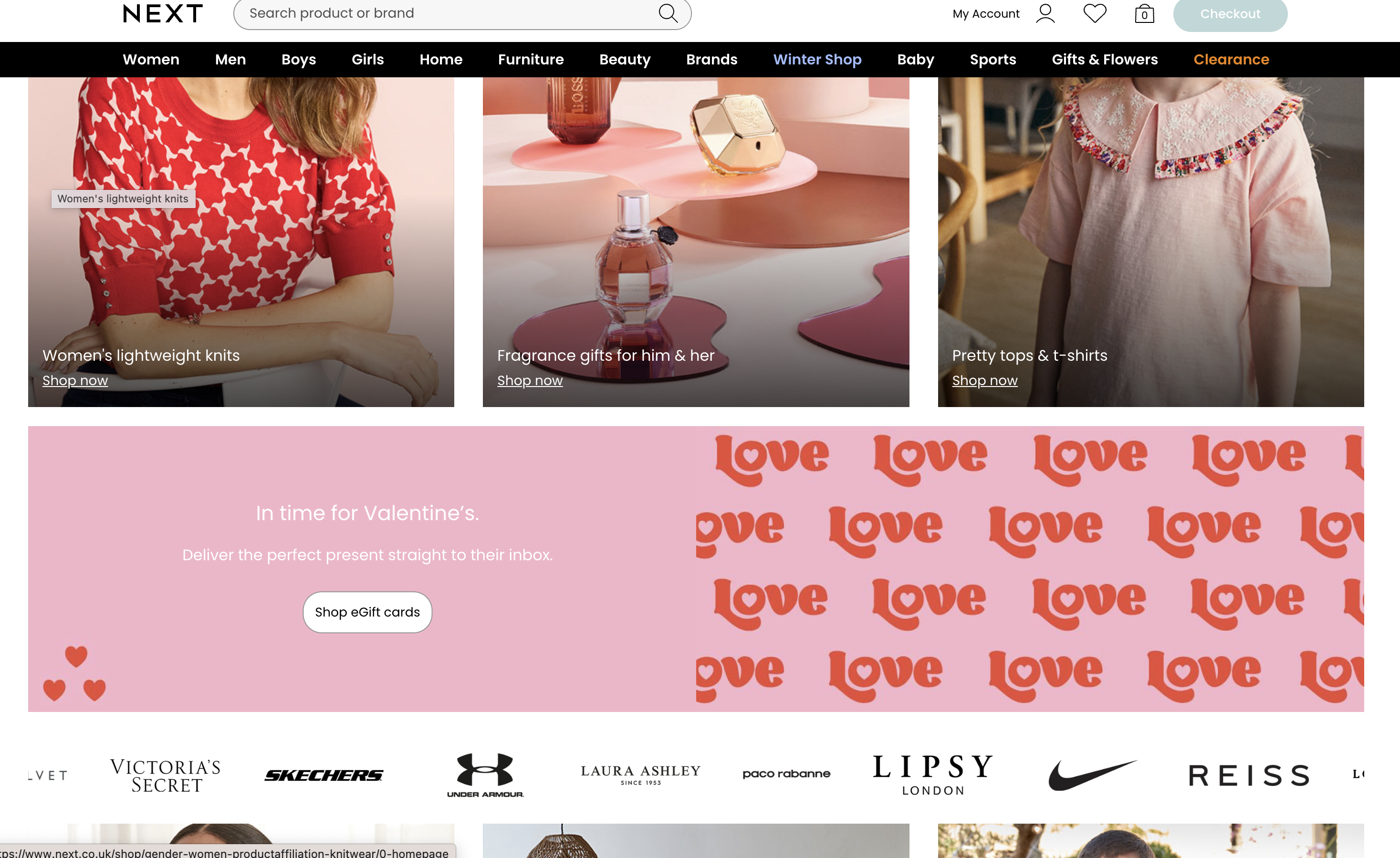

Next in focus

Although not referenced by our interviewees, Next is worth highlighting for its supply chain prowess in the UK. The retailer’s Total Platform – comprising its IT systems, warehousing, and general logistics – is increasingly sought after by third parties looking to outsource their ecommerce infrastructure rather than building it themselves.

Reiss (in February) and Gap (in August) joined the platform in 2022, and Joules – which was acquired out of administration last November via a joint venture between Next and the distressed company’s founder Tom Joule – will be fully on the Total Platform by 2024.

Next's Total Platform is used by many third-party brands

Next's Total Platform is used by many third-party brands

As referenced in relation to Amazon, any supply chain leveraged by third parties is an indication of its strength. Next certainly understands the fundamental importance of its supply chain and the need to keep evolving the structure of it to stay relevant and profitable.

Next’s stated priorities in 2022 were nearly all supply chain-related. Alongside driving profitability in fast-growing business areas and improving website performance, it listed: achieve better operating efficiencies in our online warehouse and distribution operations; improve the speed, accuracy and consistency of our online delivery service; push the boundaries of supply base to help mitigate sterling devaluation, through new sources of supply without compromising our ethics, reliability, quality or design.

The retailer will announce full-year results on 29 March, when it is expected to offer an update on progress against these priorities.

The power of partnerships

Whether it is advancing technical capability, reducing environmental footprint, improving ecommerce performance, or simply driving operational efficiency in the supply chain, forging suitable partnerships continues to be a key focus area for UK retailers.

In a complex world, retailers are clearly seeing that opportunity to improve their supply chains comes through being open to change and developing strategic partnerships.

Retailers looking to create more resilient and efficient supply chains should consider the following Five Ps.

PREPARE for continuing disruption

Within supply chain circles, it’s not uncommon to hear phrases such as “Once Brexit is done”, “after the pandemic is over”, “when we’ve shifted our overstock”, “as inflation comes down” or “when the geopolitical tension subsides”.

Adopting a positive approach in this manner is to be encouraged, but there is always going to be another major challenge on the horizon – so retailers must set up their supply chains to prepare for ongoing disruption.

PRIORITISE what makes sense to the wider organisation

As our interviews show, supply chain and IT leaders’ priorities are not always those which the wider retail organisation is focused on. More needs be done in retail to get all departments singing from the same hymn sheet; namely listening to employee demands that businesses focus more on warehouse automation and fulfilment innovations.

Outside of the supply chain, it’s clear that wider investment focuses are sucking up retailers’ budgets. In Retail Week’s Retail 2023 report, published in October 2022 featuring in-depth interviews with 57 leaders, the majority said they were currently focusing investment towards store expansion, website transformation or a combination of the two – alongside international expansion. Only two leaders mentioned supply chain investments; citing they were focused on warehousing and improving logistics.

PUT people first

For all the technology that retailers are investing in, our survey shows there needs to be greater tech support, employee engagement and salary investment for supply chain and IT staff. These people are now the cornerstone of business operations, and should be treated as such.

POWER up recruitment

It’s more important than ever to appoint the right people to lead retail supply chain and IT functions. As we’ve seen from the examples of Gymshark and JLP, a permacrisis should be when retailers seek to invest in the right talent to drive their organisations forward, not a time for delaying important recruitment decisions.

PARTNER with the right businesses

Whether it’s specific technical expertise for anything from AI-driven automation to driverless delivery, guidance on emerging legislation, or general ecommerce infrastructure outsourcing, the case studies drawn on in this report show there is always a partner on hand to help. Retailers can no longer afford to traverse supply chain disruption on their own.

Retailers looking to create more resilient and efficient supply chains should consider the following Five Ps.

PREPARE for continuing disruption

Within supply chain circles, it’s not uncommon to hear phrases such as “Once Brexit is done”, “after the pandemic is over”, “when we’ve shifted our overstock”, “as inflation comes down” or “when the geopolitical tension subsides”.

Adopting a positive approach in this manner is to be encouraged, but there is always going to be another major challenge on the horizon – so retailers must set up their supply chains to prepare for ongoing disruption.

PRIORITISE what makes sense to the wider organisation

As our interviews show, supply chain and IT leaders’ priorities are not always those which the wider retail organisation is focused on. More needs be done in retail to get all departments singing from the same hymn sheet; namely listening to employee demands that businesses focus more on warehouse automation and fulfilment innovations.

Outside of the supply chain, it’s clear that wider investment focuses are sucking up retailers’ budgets. In Retail Week’s Retail 2023 report, published in October 2022 featuring in-depth interviews with 57 leaders, the majority said they were currently focusing investment towards store expansion, website transformation or a combination of the two – alongside international expansion. Only two leaders mentioned supply chain investments; citing they were focused on warehousing and improving logistics.

PUT people first

For all the technology that retailers are investing in, our survey shows there needs to be greater tech support, employee engagement and salary investment for supply chain and IT staff. These people are now the cornerstone of business operations, and should be treated as such.

POWER up recruitment

It’s more important than ever to appoint the right people to lead retail supply chain and IT functions. As we’ve seen from the examples of Gymshark and JLP, a permacrisis should be when retailers seek to invest in the right talent to drive their organisations forward, not a time for delaying important recruitment decisions.

PARTNER with the right businesses

Whether it’s specific technical expertise for anything from AI-driven automation to driverless delivery, guidance on emerging legislation, or general ecommerce infrastructure outsourcing, the case studies drawn on in this report show there is always a partner on hand to help. Retailers can no longer afford to traverse supply chain disruption on their own.

Partner comment

Akash Gupta, co-founder and chief executive, GreyOrange

Towards the end of the pandemic, one of my colleagues was speaking to a 30-year veteran supply chain leader. This person said, and I quote, that “for the first time in a 30-year career my boss knows what I do”.

It took a series of unexpected global shocks to awaken the retail sector to the fact their supply chains were operating with 20th-century technologies in a world that now demanded 21st-century solutions.

We were delighted to partner with Retail Week in producing this valuable set of insights into the state of and outlook for retail supply chains over the next year. It has built on a similar report we produced together last year and positively points towards progress.

There are two big messages contained in the report that retail supply chain leaders and their leadership should pay attention to:

- It is clear that retailers who have taken bold steps with the technology they are deploying in their supply chain operations are winning market share. They have been able to react to external factors more effectively and, while the impacts of global disruptions continue to be felt, placing pressure on margins, the brands leveraging technology best are widening the gap.

- 21st-century technologies are data-based – algorithms (bots) that rapidly make sense of complex data. This report has highlighted the inertia and waiting game that many retailers are playing when it comes to these technologies. Their biggest fear (38%) is not to be an early adopter. This mindset needs to shift – and quickly. This technology touches us all, every day of our lives, and has done for a decade or more. This is not early adoption; this is the majority and the retailers who do not move now will not move at all.

Again, we would like to thank the team at Retail Week for producing this work and we hope you, the reader, gain valuable insight from it that will help you shape your supply chain strategy for 2024.

Supply Chain 2024 in association with GreyOrange

Megan Dunsby

Senior commercial

content editor

Ben Sillitoe

Report writer

Caroline Londoño

Account manager

Leslie Kimona

Digital marketing

operations executive

Simon Mooney

Senior marketing manager

Sam Millard

Designer

Jed Adkins

Marketing executive

Joel Barrick

Production editor